Introduction

Companies often opt to bring some or all their manufacturing processes in-house as they expand. When an ERP system manages this integration, it becomes crucial to establish a method for monitoring the raw materials necessary to produce the final products ultimately sold to customers. This list of raw materials (or recipe in the context of food) is called a bill of materials or “BOM”. Although this information can be managed outside of the system in an external database or spreadsheet, there are many benefits of managing this information within NetSuite:

No reconciliation or integration of bill of materials data between systems is required if this is managed in a single environment.

The manufacturing process will be managed in the same system where the inventory quantities are tracked, meaning the system can inform you in real-time how much of a product can be produced based on what is available in your warehouse.

- The general ledger lines for your inventory assets and costs are updated automatically when raw materials are consumed and finished goods are created.

From Cupcakes to Complex Machinery: Mastering Bill of Materials in NetSuite

Faced with these facts, let’s imagine that you own a cupcake manufacturing business and decide you would like to set up your bills of materials in NetSuite. However, before this exercise, we must acknowledge that your company will unlikely make cupcakes. Making cupcakes vastly differs from building large industrial machines, surfboards, water bottles, or products your company produces on your shop floor. Still, from a NetSuite system standpoint, they are all managed similarly. We must acquire raw materials and assemble them into subassemblies and finished goods. NetSuite’s Bill of Materials functionality helps us manage this process.

In NetSuite, there are two configurations of bill of materials:

Standard Assembly/Bill of Materials:

With this configuration, your assembly items (finished goods and subassemblies) contain the component information on the line level of the same record. NetSuite has already deprecated this configuration, so we recommend upgrading to Advanced Bills of Materials as soon as possible.

Advanced Bill of Materials (Advanced BOMs):

In this configuration, there are three records:

- The Assembly item that contains the header information about the finished good or sub-assembly.

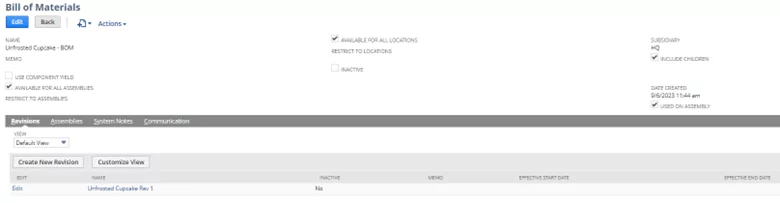

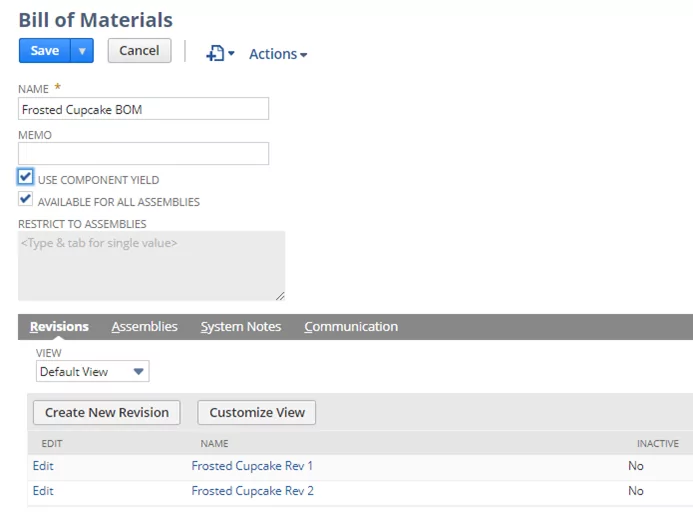

- The Bill of Materials record contains information about how the item is manufactured, and the Revision records list. These are assigned to Assembly items.

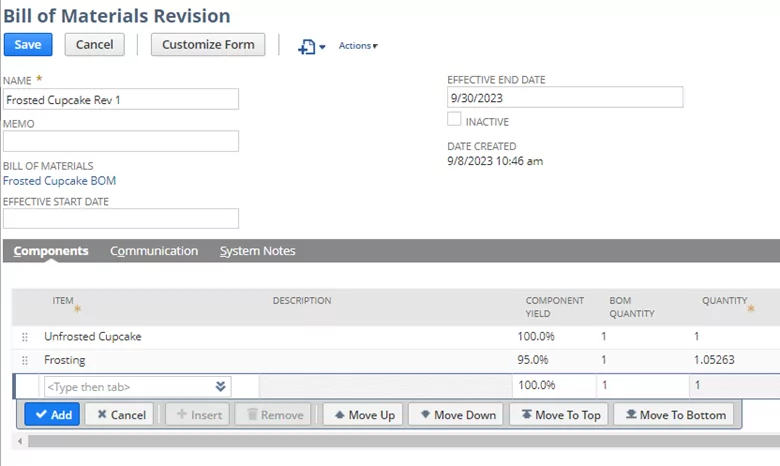

- The Revision record which contains the component information for the Bill of Materials. These are assigned to the BOM records and can be viewed from the Assembly item record.

Because it’s more common and all companies will upgrade to it eventually; the rest of the article will be in the context of Advanced BOMs. Now, back to our cupcakes example. Below is a recipe list for unfrosted cupcakes:

- All-purpose flour

- Milk

- Sugar

- Vegetable oil

- Unsalted butter

- Baking powder

- Salt

- Eggs

Further Reading Manufacturing Efficiency with NetSuite Advanced Bill of Materials

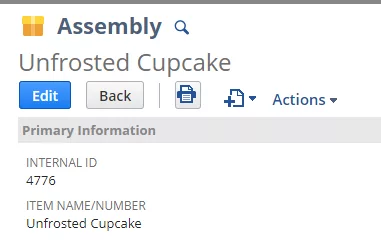

In the context of NetSuite Advanced BOMs, this is how the records for the unfrosted cupcake will be built:

The Assembly Item

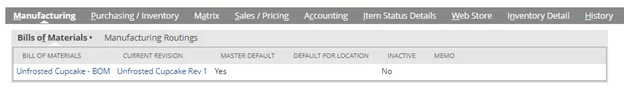

The Bill of Materials

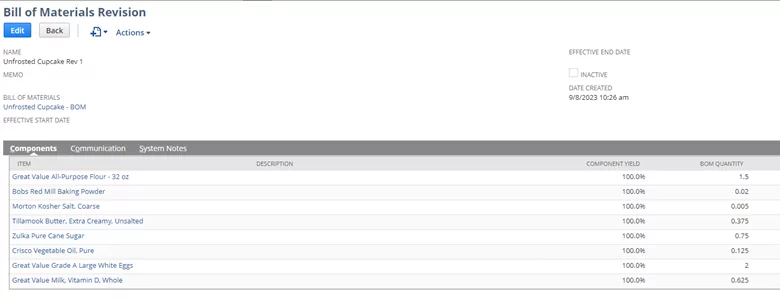

The Bill of Materials Revision (OR The Recipe)

Of course, no one wants to eat an unfrosted cupcake, so we must make and add the frosting as well! To make the frosting, we need to create another subassembly and combine these two things into the finished good. The construction for the frosting in terms of NetSuite Advanced BOMs will look like this:

User Guide for NetSuite Pricing: All You Need to Know

All you need to know about NetSuite pricing! Explore our user guide for comprehensive insights.

Download Guide

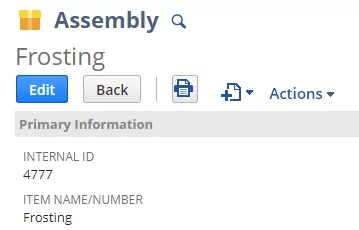

The Assembly item

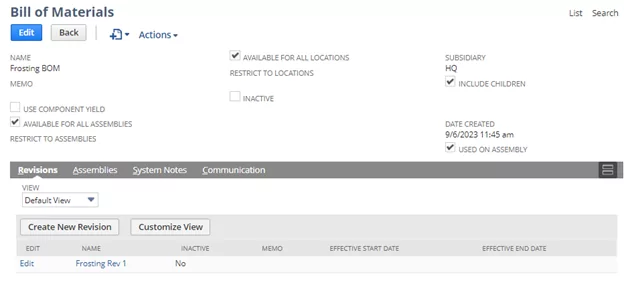

Bill of Materials

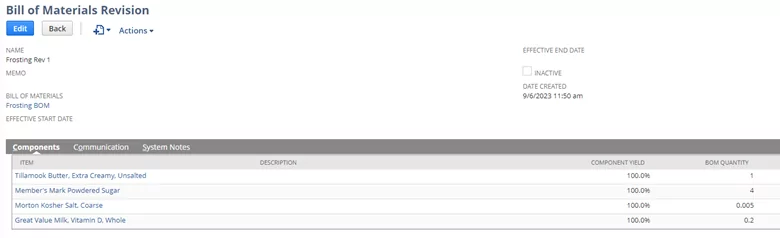

Revision

Finally, we need to make the finished good assembly item that we sell to customers, the frosted cupcake, composed of our two subassemblies.

Assembly

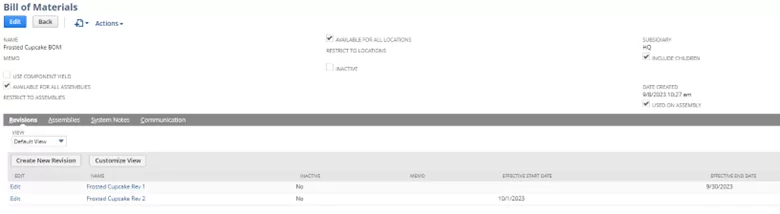

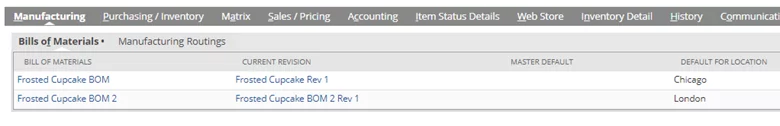

Bill of Materials

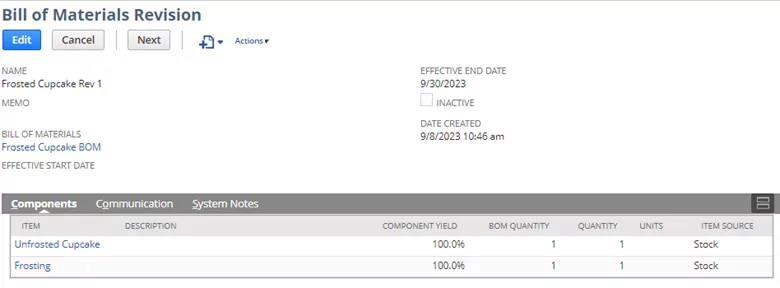

Revision

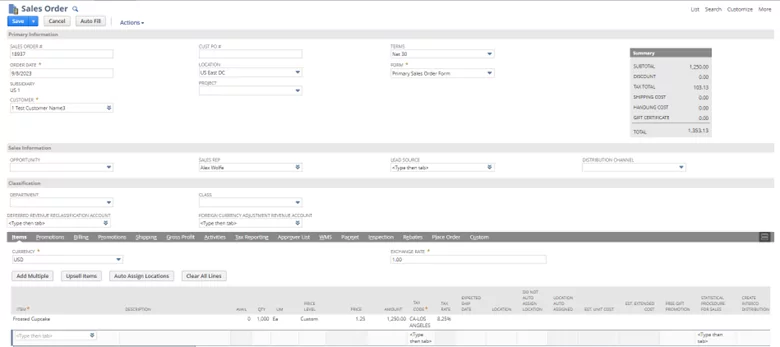

Now we can start taking sales orders for frosted cupcakes:

Following this step, we can fulfill orders using pre-made frosted cupcakes in our inventory. Additionally, we can create Unfrosted Cupcakes (a subassembly), Cupcake Frosting (another subassembly), and Frosted Cupcakes (the final product) as required by generating NetSuite Work Orders to increase their production. When we start to grasp how many cupcakes we need for future periods, we can forecast using demand and supply planning to help us prepare enough to meet expected future demand.

Discover How AlphaBOLD can Elevate your ERP Experience.

Ready to streamline your processes and drive efficiency? Schedule your demo today and embark on the path to smarter manufacturing management!

Request a DemoAdapting Bill of Materials Strategies: From Vendor Switches to Outsourced Manufacturing

Now that we understand the structure, let’s apply this to other scenarios and explain how to deal with them.

- One of the ingredients needs to be swapped out either because the recipe has changed or you are switching vendors. Let’s say the sugar you buy, Bob’s Premium Sugar, must be changed to Fred’s Gourmet Sugar. To accomplish this, we can leverage the flexibility provided by Revision records. If we know that we will switch over to Fred’s Gourmet Sugar at the beginning of the following month, then before that happens, we can create a new revision record and set the effective date to the first of next month. Not only does this allow us to create an automatic switch to the new recipe when the time comes, but it also gives us a history of the changes made to this BOM.

- Sometimes, you may need to use different components depending on location. This may be due to a cost-prohibitive ingredient not readily available in a specific region where a suitable substitute exists. In this scenario, the Assembly Item would be the same for both locations, but you would need different BOMs for different locations. Each of these BOMs will have its own effective revision on the Assembly Item record.

- During manufacturing, you may use more material than actually used up in the final product. Suppose an average or consistent percentage of scrap is produced at the end of an assembly process. In that case, mark the “USE COMPONENT YIELD” checkbox on the BOM record. Once checked, you can mark the percentage of the component you expect to end up in the finished good. On the BOM Revision record, you can mark how much of the raw material is required in the final assembly, and NetSuite will calculate how much raw material you need to start. For example, we expect to lose 5% of the frosting during the cupcake-making process, so we need to supply some extra frosting during production.

- Some companies don’t do the production themselves but instead employ a contract manufacturer’s services. In this case, if any of the raw materials are provided to the contract manufacturer, then the manufacturing process would need to be reflected in NetSuite to track how many components the contract manufacturer has to build the finished products. Regarding the bill of materials, it’s often a good idea to create a unique BOM and assign it to the contract manufacturer’s location so that it can be tracked and defaulted. This information can also be used using another NetSuite module: Outsourced Manufacturing.

Streamlining Bill of Material Management in NetSuite with AlphaBOLD's BOLDAssembly

In light of the complexities and challenges discussed in managing Bills of Materials within NetSuite, a noteworthy solution to consider is AlphaBOLD’s BOLDAssembly. This tool streamlines the BOM generation process, particularly for custom and engineer-to-order manufacturing scenarios. With features like the ability to generate Assembly Items directly from the sales order screen, a user-friendly CSV import capability for easy integration of external data, and a robust configuration record for maintaining system integrity, BOLDAssembly significantly simplifies the creation and management of BOMs in NetSuite. This enhancement speeds up the manufacturing process and ensures accuracy and efficiency in BOM management, aligning perfectly with the needs of businesses looking to optimize their NetSuite ERP experience.

Ready to Take your BOM Management to the Next Level?

Request a Demo now and experience firsthand how our BOLDAssembly solution can revolutionize your NetSuite experience.

Request a DemoConclusion

As we’ve explored the various facets of managing Bills of Materials in NetSuite, it’s clear that while the challenges can be complex, the solutions are within reach. From simplifying the process of assembling raw materials to adapting BOMs for specific manufacturing scenarios, NetSuite offers a robust framework for efficient production management. Additionally, with tools like AlphaBOLD’s BOLDAssembly, the potential for streamlining these processes is enhanced, making BOM management more accessible and less time-consuming.

If you’re navigating these challenges in your manufacturing processes or if there are unique situations we haven’t covered, our team at AlphaBOLD is here to help. With expertise in NetSuite solutions and a deep understanding of manufacturing needs, we can assist you in optimizing your BOM management and ensuring your production runs smoothly. Reach out to us at [contact information] for personalized support and to explore how our solutions can align with your business goals.