Introduction

For most manufacturers using NetSuite Advanced Bill of Materials, the issue isn’t with the feature set, capabilities, or accuracy of NetSuite BOM. Instead, the challenge increasingly lies in the complexity of configuration. Don’t misunderstand me, NetSuite is a godsend for manufacturers! However, it must be acknowledged that manufacturers are not software engineers or configuration experts. Given that NetSuite is a large and massive organization, they can’t provide detailed guidance to every client. This is where the conflict arises and where NetSuite’s Advanced Bill of Materials begins to show its limitations. To help manufacturers struggling with such issues, we have developed this blog post, which will entail a solution for every complexity common to the famous NetSuite Advanced Bill of Materials process.

Navigating the Challenges of Operational Efficiency in Manufacturing

Manufacturing is a dynamic business vertical that needs to maintain operational efficiency to score market competitiveness. But let’s face it – achieving this efficiency is often easier said than done. The challenges of an average product-based manufacturer counter are multifaceted: managing complex supply chains, ensuring cost-effectiveness, maintaining consistent product quality, and the ever-present need to stay ahead of technological advancements. It’s a tall order, and the stakes are high.

To counter all this, C-levels in the manufacturing industry often opt for a solution much like NetSuite Advanced Bill of Materials (BOM) in the hopes of a system where production planning is so streamlined that it feels like the machine knows what you need before you do. They hope for more clarity and control to steer their organizations toward efficiency and growth.

Common benefits that a Chief Manufacturing Officer would likely appreciate with a solution like NetSuite’s Bill of Materials (BOM) include:

- Streamlined Operations: There’s an expectation that NetSuite BOM will aid in organizing and managing manufacturing processes more efficiently, potentially streamlining operations by providing a centralized platform for managing all aspects of the production process.

- Real-Time Data and Visibility: It is often anticipated that the system will offer real-time insights into manufacturing operations, allowing for better decision-making. This includes hopes of assisting in managing inventory, tracking production progress, and monitoring supply chain activities effectively.

- Scalability: Many expect that as businesses grow, NetSuite’s BOM system will be scalable, adapting to increased demand, more complex manufacturing processes, or expansion into new product lines.

- Integration Capabilities: There is a common expectation that NetSuite BOM can be integrated with other systems such as ERP, CRM, and supply chain management tools, ensuring a seamless flow of information across different departments and functions.

- Improved Accuracy and Efficiency: Potential users might anticipate that by automating various aspects of the production process, NetSuite BOM will reduce the risk of human error, leading to more accurate production planning, cost estimation, and inventory management.

- Cost Reduction: It is often expected that NetSuite BOM will contribute to cost reduction by improving efficiency and accuracy, reducing waste, lowering inventory costs, and optimizing resource utilization.

- Compliance and Quality Control: Users might anticipate that the system will support compliance with industry standards and regulations and aid in implementing quality control measures throughout the manufacturing process.

- Customization and Flexibility: There is an expectation that NetSuite will offer customization options, allowing manufacturers to tailor the BOM to meet their specific needs and industry requirements.

- Enhanced Collaboration: The expectation often is that NetSuite BOM will facilitate better collaboration between different departments by providing a unified platform where all relevant information is accessible and shareable.

- Advanced Reporting and Analytics: Many expect that manufacturers will benefit from advanced reporting capabilities, enabling in-depth analysis of production efficiency, cost management, and other critical business metrics.

Ready to Transform your BOM Management with Precision?

Wave goodbye to uncertainty in production processes and embrace clarity with AlphaBOLD's expert guidance. Discover how our tailored BOM solutions can revolutionize your manufacturing efficiency.

Request a DemoNetSuite Advanced Bill of Materials Overview

Imagine solving a puzzle – each piece must fit perfectly to complete the final image. In manufacturing, a precise list of supplies, known as the Bill of Materials (BOM), serves a similar purpose in constructing products.

An Advanced BOM is more than just a list; it’s envisioned as a comprehensive blueprint that meticulously outlines every raw material, component, sub-assembly, and part required in the manufacturing process, complete with their exact quantities and specifications. It ideally extends beyond this, integrating complex routing details, production stages, and operational sequences, aiming for a seamless and error-free manufacturing journey. The Advanced BOM is the ultimate guide, navigating each twist and turn of the manufacturing maze to ensure every piece aligns perfectly to create the final, flawless product.

This system empowers manufacturers with real-time insights and data-driven decision-making capabilities. The accuracy of NetSuite’s Advanced Bill of Materials is anticipated to play a critical role in this – it’s expected to enable manufacturers to forecast needs, schedule production, and manage inventory with the confidence that stems from reliable, real-time data. The ideal result is a seamless integration of all manufacturing processes, leading to enhanced product quality, faster time-to-market, and a stronger bottom line. With NetSuite’s Advanced Bill of Materials, manufacturers aim to keep up with industry standards and set new benchmarks for efficiency and excellence.

Further read Managing Bill of Materials in NetSuite for more insights.

User Guide for NetSuite Pricing: All You Need to Know

All you need to know about NetSuite pricing! Explore our user guide for comprehensive insights.

Download Guide

Where Does It All Go Wrong?

You might be wondering, if NetSuite’s Advanced Bill of Materials is acclaimed for its capabilities, why am I emphasizing its complexity? Even under the renowned umbrella of NetSuite, this specific feature of their product suite is not immune to challenges. It’s important to peel back the layers of this sophisticated tool to understand where it might not live up to expectations.

While the Advanced Bill of Materials (BOM) is designed to be a comprehensive solution for managing manufacturing processes, the reality of implementing and using it can be quite different. Despite NetSuite’s reputation for delivering robust and efficient business solutions, the Advanced BOM feature, like any complex software, has its nuances and pitfalls that can make its practical application challenging.

Firstly, the allure of a seamlessly integrated, all-encompassing manufacturing management tool is often met with the reality of intricate configurations and settings. These complexities are not just initial setup hurdles; they extend into the system’s day-to-day operations and long-term maintenance. The anticipated ease of use and flexibility may not be as straightforward as expected, especially when adapting the system to fit unique manufacturing processes or specific industry needs.

Moreover, the integration of NetSuite’s Advanced BOM with other critical business systems – a theoretically advantageous feature – can present its own set of challenges in practice. Ensuring smooth data flow and compatibility between various platforms, such as ERP, CRM, or supply chain management tools, often requires more effort and expertise than initially anticipated.

These challenges, among others, serve as a reminder that the decision to implement NetSuite’s Advanced Bill of Materials should be approached with a comprehensive understanding of not only its potential benefits but also its limitations and the real-world difficulties it may entail.

Step Ahead in Manufacturing with Advanced BOM Capabilities!

Discover the power of our BOLDAssembly solution in transforming your NetSuite operations and witness the unmatched efficiency it brings to your BOM management.

Request a DemoAlphaBOLD BOLDAssembly – BOM Generator

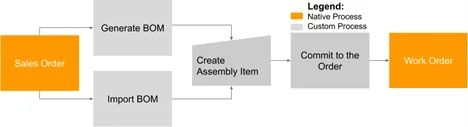

The gap in the traditional BOM process becomes evident as we’ve explored the capabilities and shortcomings of NetSuite Advanced Bill of Materials and the importance of effective BOM management. This gap is precisely what AlphaBOLD BOLDAssembly – BOM Generator aims to bridge. Recognizing the challenges production managers and engineers face in configuring Assembly Items quickly and accurately, AlphaBOLD has innovated a solution tailored to the dynamic needs of custom order manufacturing.

AlphaBOLD BOLDAssembly – BOM Generator is a groundbreaking tool developed on top of NetSuite’s platform. It revolutionizes the process of generating Assembly Items directly from the order screen. This tool simplifies the complex, often cumbersome task that production managers and administrators face in traditional ERP systems. By streamlining this process, BOLDAssembly significantly reduces delays in order fulfillment, enhancing manufacturing efficiency with BOM and responsiveness to customer needs.

For manufacturing companies navigating the demanding landscape of custom order processing, AlphaBOLD BOLDAssembly is not just a tool; it’s a strategic advantage. It enables rapid, just-in-time construction of BOMs and ensures that the production floor receives accurate specifications without the typical bottlenecks.

Discover the Difference with AlphaBOLD BOLDAssembly!

Ready to experience this transformation in your BOM process and elevate your order fulfillment efficiency?

Request a DemoConclusion

As we’ve walked through NetSuite’s Advanced Bill of Materials and explored the transformative capabilities of AlphaBOLD BOLDAssembly – BOM Generator, one thing is abundantly clear: the landscape of manufacturing efficiency is evolving. In an industry where precision, speed, and adaptability are not just assets but necessities, these tools represent more than just technological advancements; they are the harbingers of a new era in manufacturing.

NetSuite’s Advanced BOM empowers businesses to manage multiple BOMs, perform detailed revision management, and enjoy seamless integration with supply chain operations. All these features culminate in an enhanced ability to analyze, forecast, and execute with unprecedented precision.

On the other hand, AlphaBOLD’s BOLDAssembly – BOM Generator is a beacon of innovation, especially for those in the build-to-order and engineer-to-order manufacturing sectors. By simplifying the generation of Assembly Items directly from the order screen, this tool significantly cuts down the time from order to production. Therefore, AlphaBOLD BOLDAssembly offers not just an improvement to existing processes but a complete overhaul of how production planning and execution are perceived and achieved.