Introduction

NetSuite has introduced Material Requirements Planning functionality as part of the 2020.2 updates. We have been testing it with a few clients, and we are delighted with what it brings to the table. In this article, I will focus most of my attention on explaining the NetSuite MRP benefits and how it can improve overall material planning and forecasting. Even though it is not a guide, my text is meant to help you decide whether this feature can satisfy your planning needs.

What is NetSuite MRP, and What Can it Do?

Material Requirements Planning (MRP) is a ‘production planning, scheduling, and inventory control system used to manage manufacturing processes’ (source: Wikipedia). In NetSuite, it is part of Demand Planning functionality, and you cannot use it, unless this functionality is provisioned in your system. With 2020.2 updates, you can enable MRP in the ‘Enable Features’ section of NetSuite.

Why would you use it? Suppose you are working with NetSuite’s Demand Planning, and you are not satisfied with how NetSuite’s legacy Supply Plan feature is handling purchasing and production recommendations., In that case, you must test the new MRP functionality. It will not only improve the planning, but it will also provide the visibility and the traceability that the legacy Supply Plan does not provide.

Streamline your Production with NetSuite Solution

Enhance your production efficiency with NetSuite MRP. Partner with AlphaBOLD to optimize your manufacturing processes and drive growth. Let's streamline your operations together.

Request a DemoPlanning Workbench

In NetSuite, the planner interacts with the MRP functionality through a powerful interface called ‘Planning Workbench’.’ As illustrated below, there are four main areas (panes) of the Workbench that help production planners make their manufacturing and procurement decisions.

1. NetSuite MRP: Item Filters:

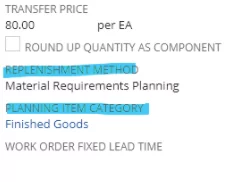

Once the MRP is enabled, you will need to create lists that will to help you group and categorize your items. Typically, ‘planning categories’ can be ‘components’ (raw material) and ‘finished goods’.’ Nevertheless, you can also categorize your items by channels or other product categories/sub-categories you may have,; for example, : metal products, electronics, rubber products, accessories, etc.

The goal here is to have a logical categorization of items so that it is simple to review the planning messages for specific item types (as shown in pane #3).

One important point here, once you set up the category lists, you need to set these values on item records as well. The fields that need to be populated on the item record are shown below.

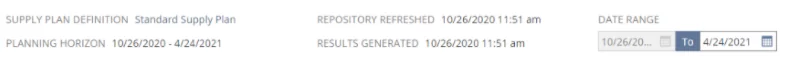

2. Supply Planning Window:

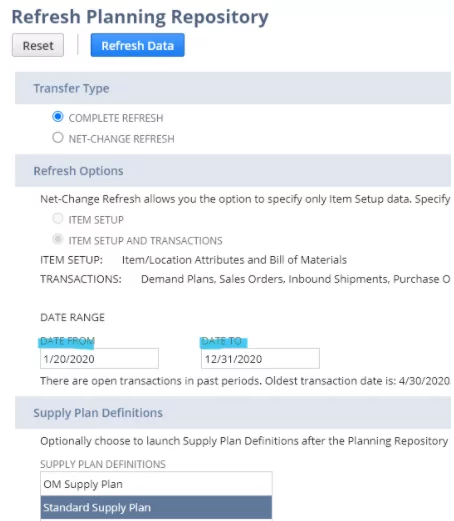

Before the data can be analyzed in the ‘Planning Workbench’, the planner must refresh the ‘Planning Repository’.’ This step generates the supply / demand forecasts and ‘planned orders’ based on your configuration and direct and indirect demand for your products. The date range illustrated in area #2 above is set on the ‘Planning Repository’ refresh screen (see below).

Lastly, when you look at the ‘Supply Plan Definitions’ field in the image above, you will see that there can be more than one supply plan definitions. Now, what does this mean?

‘Supply Plan Definition’ is essentially an instance of a supply plan. Think of it as a supply plan version.

Read More: Supply Change Order Management Within NetSuite MRP

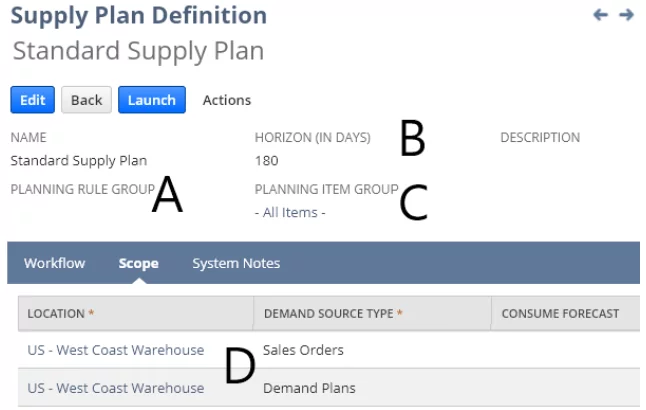

On the supply definition record, you will set:

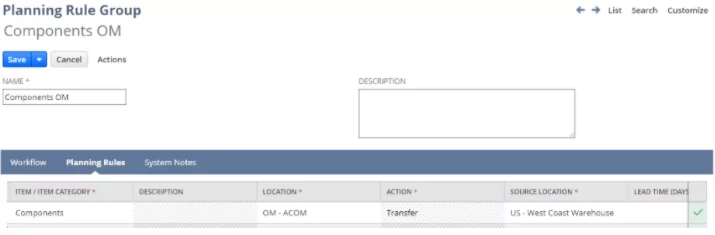

A. Planning Rule Group:

Think of the ‘planning rule group’ as an alternative to a ‘distribution plan’..’ In the rule group, you will define, for example,: how (from which location) the raw material will be transferred to the contract manufacturing warehouse for final production.

The image below shows, that the rule states that the components (planning item category) are transferred from the company’s warehouse to the contract manufacturing location. In the planning rules section, you can also specify the lead time for transfers, and that time would automatically be ‘baked-in’ during the system’s planning calculations.

B. Horizon:

This is a planning horizon for your supply plan calculations. The default is 180 days (about 6 months).

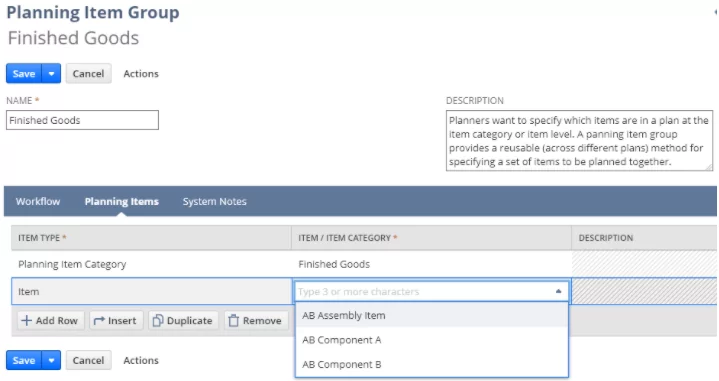

C. Planning Item Group:

Earlier, we covered ‘Planning Item Categories,’ which can be grouped in ‘Planning Item Groups’ with other categories and specific SKU’s if needed.

NetSuite Supply Allocation Guide

Navigate supply allocation efficiently with our NetSuite guide. Streamline operations effortlessly

Download Guide

D. Scope:

Lastly, under the scope tab, you will designate the demand source for your supply plan. You have two options, Sales Orders and / or Demand Plan. Do not forget to specify this information on the supply plan definition. Otherwise, the system will not create ‘Planned Orders’ (supply) based on the your product’s demands.

3. Results Summary:

Once the repository is refreshed, all items that follow the MRP replenishment method will appear on the planning workbench (pane #3 above). In the columns shown below, the planner can review the on-hand inventory, on order quantities, and any late demand (based on the filters selected in pane #1).

The ‘Message / Order Counts’ section will list (from right to left) demand and supply columns. Depending on what types of items are listed in this table, the demand column would show the Sales Orders or Demand Plans (for finished goods) or planned Work Orders (for components / raw material). The supply column would show (per skuSKU) all of the planned Purchase Orders for components and / or regular inventory items (that use MRP replenishment method) or planned Work Orders to produce f finished goods.

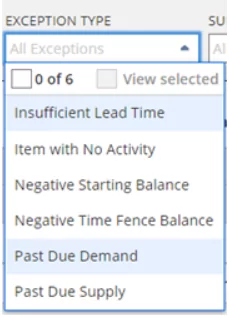

4. Message Order / Filters:

Pane # 4 lists some filters that further enhance the planner’s work-bench experience. It makes it easy to filter out actions or supply types that you do not want to see in pane #3.

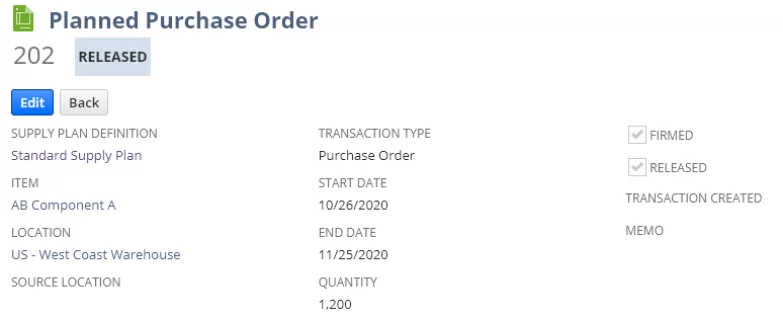

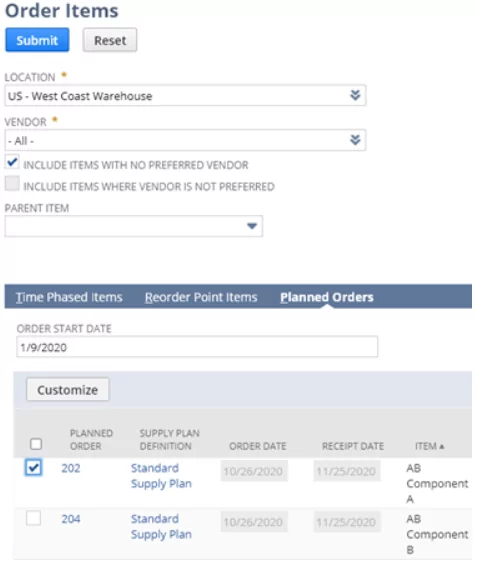

Planned Orders

Above, you must have noticed the concept of ‘planned orders’.’ The MRP feature introduces these new records. They are generated automatically based on what items the system recommends you purchase or produce.

Once firmed and released, these records can be turned into real Purchase Orders on NetSuite’s standard ‘Order Items’ screen. This is one very powerful feature that makes this functionality very attractive for production planners.

NetSuite MRP: What Else Do You Need to Know?

I am sure that the writeup above got you excited! Well, hold-on. Certain limitations and configuration adjustments may impact your system, of which you should be aware before you proceed.

- Demand Planning: Do not forget, you must have the Demand Planning feature in NetSuite before you can use MRP.

- Advanced BOM functionality: When you enable MRP, you also must enable Advanced BOM functionality. This can be a big configuration change as it separates the Assembly Items from the Bill of Materials setup. We advise you to test this feature thoroughly in a Sandbox environment (or Release Preview environment, if available) to ensure that Advanced BOM’s will work for you.

- Reporting: As this is a brand-new feature, no ‘canned’ (out-of-the-box) reporting for MRP is provided. We worked with some clients to build Analytics Work Books while using Planned Orders as a data set. We discovered that Through Planned Orders, you could not natively join with BOM Revisions (Advanced BOM functionality). To overcome this limitation, we created a custom field on the item record (assembly item) that would become a native link to our revision. We then exposed the components in one report and calculated the component demand in our Workbook. Feel free to reach out to us if you want to know more.

- Repository Refresh Scheduling: We did not find a way to automatically refresh the repository. The user must initiate these refreshes manually. We feel that this is a limitation, and we are hopeful that this capability is coming in future releases.

Read More: BOLDAssembly – BOM Generator

Drive Efficiency with NetSuite Solutions!

Simplify your manufacturing resource planning with NetSuite MRP. Contact AlphaBOLD to optimize your processes and achieve seamless operations. Get started today!

Request a DemoFinal Thoughts on NetSuite MRP

I hope this article was detailed enough to introduce the MRP concepts to you as they were designed in NetSuite. With each new enhancement, this system is getting closer to a ‘fully-baked’ planning solution. If you are struggling with the production planning and you are currently doing it in Excel, we strongly suggest giving this feature a test. If there is a slight chance that you can leave Excel behind, we think that this a chance worth taking.